Alcion specialises in chemical recovery from industrial discharge

Alcion specialises in air purification and the recovery of chemical substances and by-products from aqueous and gaseous effluent using chemical recycling technology in line with a circular economy strategy.

Alcion, brand of SEDE, is a specialist in the circular economy of chemical products. It provides support to industrial companies in the recovery and reduction of air pollution and odorous emissions.

Alcion offers consulting and engineering services for turn-key solutions for treating air and polluted water without a recovery component.

Alcion has developed two processes :

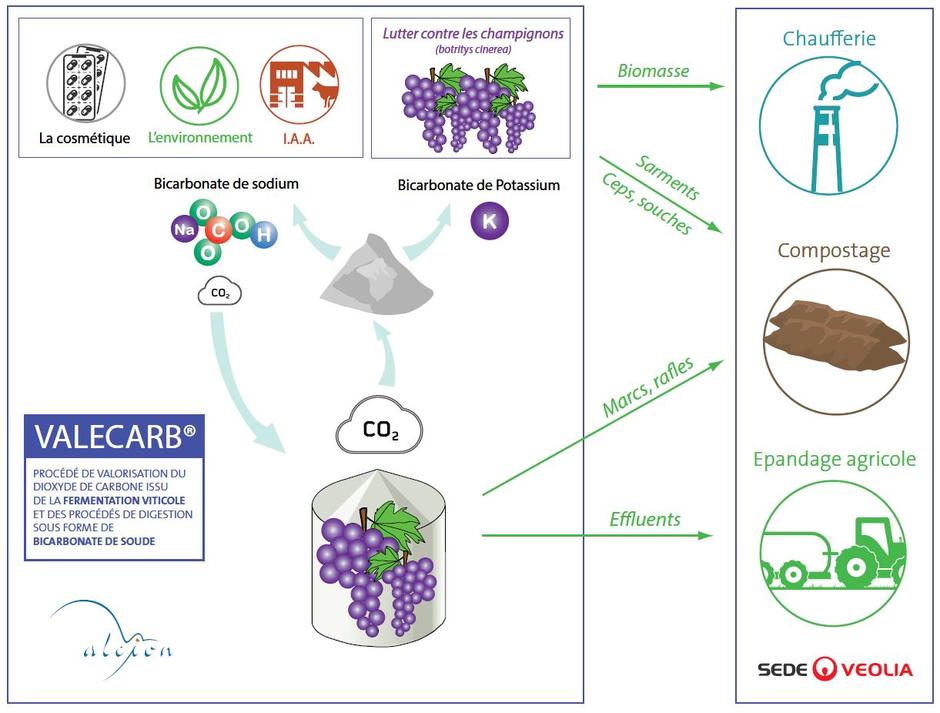

ValeCarb : Carbon dioxide recovery from alcoholic fermentation and digestion processes in the winemaking industry.

ValeAz : A patented process to recover ammonia by treating sludge from gas scrubbers at composting facilities, digestates and industrial

effluent.

ValeCarb process

Objectives

The ValeCarb process is based on a system of recovering carbon dioxide (CO2) produced during alcoholic fermentation, converted to sodium bicarbonate. For this process to work, it is important to find the most efficient way of extracting CO2 from fermentation tanks. The process offers solutions in terms of protecting staff from CO2 emissions as well as operational concerns (admissible pressure of fermentation tanks, risks of overflow, opening of outlets when tanks are in operation, etc.).

Aims

› Recover winemaking by-products and supply them to other industrial channels,

› Improve the wine industry's carbon footprint,

› Enhance staff safety.

Initial outcomes

› A CO2 capture and conversion system launched to market,

› Improved yield from CO2 > sodium bicarbonate conversion.

ValeAz process

ValeAz technology is a solution for recycling ammonia from treated sludge. Ammonia-laden air emitted by composting facilities is treated in an acid scrubber which releases a sludge. This effluent is then treated by the ValeAz process which includes a vacuum stripping step.

This produces a 20% concentrated ammonia solution which can be recycled for various applications including steam treatment, chemical production and agriculture. It also generates sodium nitrate used to prevent septicity in sanitary sewers.

Depending on the specific needs of the industrial company, ValeAz is available in both stationary and mobile units. This process can also be adapted to liquid digestates.

Château Montrose: a success story

Château Montrose (Gironde) has become the world’s leading producer of sodium bicarbonate from fermentation CO2 using the ValeCarb process.